You have no items in your shopping cart.

Technical information

Within the ultra-pure fluid transfer industry there is a wide variety of formulations that could be used in each product. This section’s purpose is to offer some details on the different materials used. All materials and information cannot be listed - for specific inquiries, please see Contact Us.

Hose Selection Guide

- Size – ID, OD and length

- Temperature – of the material conveyed and the surrounding environment.

- Application – conditions of use.

- Material – being conveyed, type and concentration.

- Pressure – to which the assembly will be exposed to.

- Ends – style, type, orientation, attachment methods, etc.

- Delivery – testing, quality, packaging and delivery requirements.

Tubing Selection Guide

- What fluid(s) are to be transported?

- What range of temperatures will the tubing be subjected to?

- What is the maximum line pressure or vacuum?

- Are specific dimensional tolerances required?

- What degree of the tube flexibility is desired?

- What are the conditions of the ambient environment?

- Is there a minimum bend radius required?

- Is clarity of tubing important?

- What method(s) of cleaning and/or sterilization are to be employed?

- Will any fluid loss or alteration through sorption (absorption/adsorption) affect your final results?

- What regulatory documentation is needed? (i.e. FDA, NSF, ISO 10993, USP, etc.)

- Is resistance to flexural fatigue or abrasion important?

- Is particle spallation of tubing a concern while used in a peristaltic pump?

- Will the level of extractability affect the tubing an issue?

- Is disposal of contaminated tubing an issue?

- Will particle entrapment resulting in an increased risk of bacterial growth be a concern?

Tubing Materials

Polyvinlidenefluoride – PVDF

Background

PVDF is often referred to by one of it’s trade names, Kynar®. It was designed primarily for applications requiring excellent chemical

resistance, high levels of purity, and superior mechanical properties. PVDF is often used as a lining or protective barrier in chemical applications.

Key Properties

- Superior tensile properties and impact strengths

- Excellent resistance to creep and fatigue

- Excellent mechanical properties over a broad temperature range

- Excellent radiation resistance

Additional Properties

- Excellent resistance to cut-through

- High dielectric strength over a wide temperature range

- Chemically resistant (all common solvents, acids and bases)

- Chemically inert

Perfluoroalkoxy – PFA/MFA

Background

PFA was developed to increase the continuous service temperature of FEP resin. Melt processability allows PFA to be processed in longer continuous lengths than PTFE.

Key Properties

- Excellent clarity and flexibility

- Maximum working temperature 500°F (260°C)

- Combines attributes of PTFE and FEP

- Chemically resistant to all common solvents

- Maintains a mechanical strength at high temperatures

- Available in high purity grades

- Chemically inert

Additional Properties

- Excellent solvent resistance

- Low gas permeability

- Smoother surface texture

- Ultra-low levels of ionic extractables

- ETO, e-beam and autoclave sterilizable

- Flame resistant: UL 94 VO

Polyetheretherketone – PEEK

Background

PEEK™ is a high performance engineered polymer with amazing strength and heat resistant properties. PEEK™ has become a popular replacement for metal in applications such as aerospace where weight is a primary concern. It has also become the gold standard for HPLC analytical science applications due to its purity, high burst pressure, and chemical resistance. In medical applications PEEK’s biocompatibility, high tensile strength, and lubricity have made it an ideal replacement for stainless steel. PEEK™ is a very rigid plastic with excellent lubricity and is tan in its natural color.

Key Properties

- Ideal replacement for stainless steel for weight and chemical compatibility

- Exceptional torsional stability

- Thermoformable

- Resistant to gamma radiation

- High burst pressure

- High repeat autoclavability

Additional Properties

- High strength

- High temperature resistance

- Outstanding resistance to chemicals and solvents

- Excellent impact and wear resistance

- Low flammability value

- Excellent creep and fatigue resistance

- Excellent hydrolysis resistance

Polyethylene Terephthalate Polyester – PET

Background

PET resin has become the polymer of choice for price sensitive applications requiring excellent mechanical and physical properties. ZEUS specializes in the extrusion of PET heat shrink available in lay-flat form.

Key Properties

- Clarity

- UV resistant (with additive)

- Extremely strong

- Shrink-back temperature begins at 180°F (82°C)

- Operating temperature exceeding 338°F (170°C)

- Low cost resin

Additional Properties

- Excellent dielectric strength

- Extremely low water absorption

- Very lightweight

Polyethylene – PE

HDPE

- Maximum temperature: 150° F (66°C) - short duration; 130°F (54°C) - long duration

- Inherent lubricity

- Excellent chemical resistance

- Hardest and stiffest version of PE

- More resilient than LDPE

- Resistant to sunlight and UV attack

- Tensile strength: 3,200 - 4,500 psi

MDPE

- Maximum temperature: 150°F (66°C) - short duration; 130° F (54°C) – long duration

- Tensile strength: 1,900 – 4,500 psi

- Excellent chemical resistance

- Inherent lubricity

- Other properties are between HDPE and LDPE

LDPE

- EVA available as a Lay-flat

- Maximum temperature: 150°F (66°C) - short duration; 130° F (54°C) – long duration

- Inherent lubricity

- Excellent chemical resistance

- Softest and most flexible version of PE

- High elongation giving it excellent impact strength

- Tensile strength: 1,200 - 4,000 psi

Ethylenetetrafluoroethylene – ETFE

Background

ETFE is used in applications requiring excellent impact resistance and good resistance to stress cracking. The resin maintains these properties up to its continuous working temperature of over 300°F (149°C). ETFE is the resin of choice for applications requiring a fluoropolymer with superior mechanical properties.

Key Properties

- Excellent impact resistance

- Increased durability and stiffness over other fluoropolymers

- Higher pressure rating than other fluoropolymers

- Higher tensile strength and creep resistance than other fluoropolymers

- Greater crush resistance than other fluoropolymers

Additional Properties

- Gamma, ETO and e-beam sterilizable

- Maximum working temperature 302° F (150°C)

- Chemical resistant

- Flame rating: UL 94 VO

- Limiting oxygen index 30

Polytetrafluoroethylne – PTFE

Background

Originally discovered in the 1930’s by DuPont® scientist Dr. Roy Plunkett, PTFE was first used in the top secret Manhattan Project during WWII. DuPont® commercialized PTFE under the tradename Teflon® in the late 1940’s. Extrudable grades of PTFE were commercialized later and in 1966 ZEUS was founded and began development of advanced manufacturing processes for PTFE. _ The unique properties of PTFE has made it the polymer of first choice for many advanced applications. With the lowest coefficient of friction of any polymer and an extremely broad working temperature range, PTFE has been designed into products from advanced medical devices to high temperature industrial equipment. Because of it’s unparalleled chemical resistance and extreme chemical inertness, PTFE has become a choice plastic for the chemical and analytical sciences industries.

Key Properties

- Very lubricious - Lowest coefficient of friction of any polymer

- Working temperature range -454°F (-270°C) to 500°F (260°C)

- Chemically resistant (all common solvents, acids and bases)

- Chemically inert

- Low extractables

- Excellent dielectric insulation properties

Additional Properties

- Biocompatible - Certified USP Class VI

- Flame resistant: UL 94 VO

- Limiting oxygen index greater than 95

- ETO and autoclave sterilizable

Fluorinatedethylenepropylene - FEP

Background

The development of PTFE was a significant breakthrough in polymer sciences. The special processing requirements of PTFE led researchers to develop a melt-processable version of PTFE resulting in FEP. This new resin was compatible with existing processing methods and equipment. Melt processability also allowed for long continuous extrusions of FEP in applications such as wire and cable.

While similar to PTFE in properties FEP has some distinct differences. It has a slightly higher coefficient of friction, lower continuous service temperature, and is more transparent than PTFE. FEP also offers lower gas and vapor permeability properties and excellent UV resistance.

Key Properties

- Excellent coefficient of friction

- Chemically resistant and inert

- Gamma, ETO, e-beam and autoclave sterilizable

- Maximum working temperature 400°F (204°C)

- Excellent transmission of ultraviolet rays

- Lower gas and vapor permeability than PTFE

- Low absorption of solvents (less than 1%)

- Increased translucence compared to most plastics

Additional Properties

- Excellent dielectric insulation properties

- Melt weldable and thermoformable

- Biocompatible - Certified USP Class VI

- Environmentally stable

- Flame Rating: UL 94 VO

- Limiting oxygen index greater than 95

Tretrafluoroethylene Hecafluoropropylene Vinylidene Fluoride - THV

Background

THV resin is a terpolymer of tetrafluoroethylene, hexafluoropropylene and Vinylidene fluoride. THV is the most flexible fluoropolymer available and has the highest degree of optical clarity. Combined with the traditional chemical and environmental resistance of fluoropolymers, THV is an ideal choice for many applications.

Key Properties

- Excellent barrier properties

- Exceptional optical clarity

- Good UV transmittance

- Easily weldable

Additional Properties

- High limiting oxygen index: Does not support combustion

Clamp Selection Guide

- What is the tubing or hose ID?

- What is the inserted fitting/connection ID?

- What is the maximum pressure or vacuum?

- Is there any band width specifically required?

- Will this be a single use application or one that requires multiple removals?

- Is there a material preference?

Filter Selection Guide

- What fluid(s) are to be transported?

- Flow rate – maximum inlet or outlet

- What is the connection size?

- What is the range of temperature?

- What is the pressure?

- What is the micron size?

- What is the viscosity of the fluid(s)?

Fittings Material

Nylon – Natural (NN)

Temperature Range -50 °F to 275 °F (135 °C) • Pressure 125 psi @ 70 °F 6/6 Nylons exhibit good tensile strength, moderate stiffness and high impact resistance. They're resistant to fuels, lubricants and many chemicals, but vulnerable to attack by phenols, strong acids and oxidizing agents. MN White Medical Nylon is made from the same resin as Natural Nylon, but has an FDA compliant white colorant added.

Natural Kynar (NK)

Temperature Range -80 °F to 226 °F • Pressure 260 psi @ 70 °F. NK material can be autoclaved to 285 °F (140 °C) and meets USP Class VI requirements. Generally, chemically resistant to: most acids, salts, weak bases, halogenated Natural Kynar® (NK) solvents, alcohols, nuclear and UV radiation, oxidants, ozone and deionized water

High Density Polyethylene (HDPE)

HDPE complies with FDA 21 CFR 177.1520 when used unmodified for the manufacture of food contact articles. HDPE has various applications for use in medical products and devices. It has excellent resistance to chemicals, but exhibits lower thermal resistance than other materials. It is a softer material than nylon or polypropylene and much softer than Kynar®.

Antimicrobial (Protected) (AG)

Antimicrobial protected Ag fittings are available in Nylon, Kynar®, Polypropylene and HDPE. These fittings incorporate natural silver ion protection to guard against microbial colonization and biofilm formation on their surfaces. Kynar ® Ag fittings (AGNK) are autoclavable.

CrystalVu (CVU)

CrystaVu™(polyolefin): A clear transparent alternative to polycarbonate containing no Bisphenol-A (BPA) - will not deform at temperatures to 180 °C (356 °F). Autoclavable - enhanced characteristics compared with polycarbonate include: superior chemical resistance; no crazing with multiple autoclave cycles plus gamma and EtO Sterilization compatibility - USP Class VI, EU 2002/72/EC.

ADF Polypropylene (PP)

A polypropylene formulated for biomedical and bioprocess applications. Temperature Range -9 °F to 150°F (66 °C) • Pressure 125 psi @ 70 °F. Meets FDA requirements 21 CFR 177.1520(a)(3)(i) and (c)3.1a. PP material has a Drug Master File listing. It is radiation stable and is resistant to solvents, chemicals, water and other inorganic environments. It resists most strong mineral acids and bases; however, it is subject to attack by oxidizing agents.

Fittings Selection Guide

- What fluid(s) are to be transported?

- What range of temperatures will the tubing be subjected to?

- What is the maximum line pressure or vacuum?

- Are specific dimensional tolerances required?

- Will particle entrapment result in increased risk of bacterial growth be of a concern?

- What are the conditions of the ambient environment?

- What regulatory documentation is needed? (i.e. FDA, NSF, ISO 10993, USP, etc.)

- Is disposal of contaminated tubing an issue?

Tubing to Fitting Compatibility

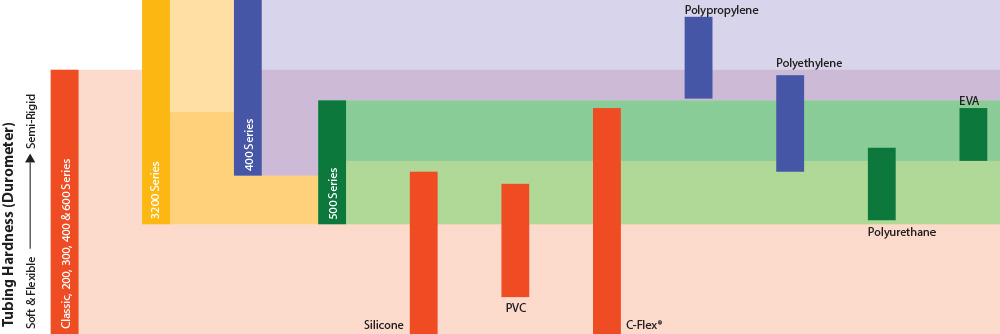

The following chart relates tubing material and hardness characteristics to typical performance with Nordson MEDICAL barbs. To use the chart, identify your durometer hardness, read across the chart to locate your material and identify the barb series that you should consider.

Fittings Barb Series Selection Guide

Unlike other suppliers, Nordson MEDICAL doesn't attempt to accommodate many tubing properties with one barb design only. Nine designs are offered, each with unique characteristics to enable you to tailor connection performance to your needs. Review the descriptions for each of the styles to determine what's best for your application.

200 Series

The 200 Series offers outstanding performance characteristics when used with flexible tubing. Tubing is expanded by 50% above its nominal inside diameter, permitting high-pressure capabilities.

200 Series Technical Information

| 200 Series Barb Dimensions | Tube Internal Diameter | ||||

|---|---|---|---|---|---|

| Barb Size | Barb OD | Barb ID | Decimal | Fraction | Metric |

| 210 | 0.094 | 0.047 | 0.063 | 1/16" | 1.6 mm |

| 220 | 0.141 | 0.070 | 0.094 | 3/32" | 2.4 mm |

| 230 | 0.188 | 0.094 | 0.125 | 1/8" | 3.2 mm |

| 240 | 0.234 | 0.117 | 0.156 | 5/32" | 4.0 mm |

| 250 | 0.282 | 0.141 | 0.188 | 3/16" | 4.8 mm |

| 260 | 0.375 | 0.188 | 0.250 | 1/4" | 6.4 mm |

300 Series

The 300 Series offers outstanding performance characteristics when used with flexible tubing. Tubing is expanded by 35% above its nominal inside diameter, permitting high-pressure capabilities in the larger tube sizes. This barb style provides high flow efficiency and excellent tensile strength.

300 Series Technical Information

| 300 Series Barb Dimensions | Tube Internal Diameter | ||||

|---|---|---|---|---|---|

| Barb Size | Barb OD | Barb ID | Decimal | Fraction | Metric |

| 360 | 0.338 | 0.192 | 0.250 | 1/4" | 6.4 mm |

400 Series

The 400 Series provides easy assembly while maintaining excellent pressure and tensile capabilities. Originally created for semi-rigid tubing, this series is preferred for applications where tensile/pressure properties are not highly critical, or when ease of assembly is desired. The 400 Series expands the tubing 25% above its nominal inside diameter.

400 Series Technical Information

| 400 Series Barb Dimensions | Tube Internal Diameter | ||||

|---|---|---|---|---|---|

| Barb Size | Barb OD | Barb ID | Decimal | Fraction | Metric |

| 410 | 0.078 | 0.046 | 0.063 | 1/16" | 1.6 mm |

| 420 | 0.117 | 0.068 | 0.094 | 3/32" | 2.4 mm |

| 430 | 0.156 | 0.092 | 0.125 | 1/8" | 3.2 mm |

| 440 | 0.206 | 0.125 | 0.156 | 5/32" | 4.0 mm |

| 445 | 0.213 | 0.125 | 0.170 | — | 4.3 mm |

| 450 | 0.234 | 0.137 | 0.188 | 3/16" | 4.8 mm |

| 460 | 0.313 | 0.184 | 0.250 | 1/4" | 6.4 mm |

500 Series

The 500 Series profile is composed of blended radii giving it the distinct look. Each barb is designed to accommodate a range of tube sizes and tube types. Consideration should be given to flow restriction, pressure capability, and the force required for assembly of the tube.

500 Series Technical Information

| 500 Series Barb Dimensions | Tube Internal Diameter | ||||

|---|---|---|---|---|---|

| Barb Size | Barb OD | Barb ID | Decimal | Fraction | Metric |

| 004 | 0.102 | 0.060 | 0.063 | 1/16" | 1.6 mm |

| 007 | 0.129 | 0.076 | 0.094 | 3/32" | 2.4 mm |

| 013 | 0.164 | 0.096 | 0.125 | 1/8" | 3.2 mm |

| 025 | 0.208 | 0.122 | 0.156 | 5/32" | 4.0 mm |

| 035 | 0.264 | 0.155 | 0.188 | 3/16" | 4.8 mm |

| 055 | 0.335 | 0.197 | 0.250 | 1/4" | 6.4 mm |

| 065 | 0.425 | 0.250 | 0.312 | 5/16" | 8.0 mm |

| N070 | 0.483 | 0.262 | 0.375 | 3/8" | 9.5 mm |

| L070 | 0.483 | 0.251 | 0.375 | 3/8" | 9.5 mm |

| T070 | 0.483 | 0.290 | 0.375 | 3/8" | 9.5 mm |

| N080 | 0.613 | 0.333 | 0.500 | 1/2" | 12.7 mm |

| L080 | 0.613 | 0.319 | 0.500 | 1/2" | 12.7 mm |

| T080 | 0.613 | 0.356 | 0.500 | 1/2" | 12.7 mm |

| N090 | 0.718 | 0.390 | 0.625 | 5/8" | 16.0 mm |

| L090 | 0.718 | 0.374 | 0.625 | 5/8" | 16.0 mm |

| T090 | 0.718 | 0.374 | 0.625 | 5/8" | 16.0 mm |

| N100 | 0.853 | 0.465 | 0.750 | 3/4" | 19.0 mm |

| L100 | 0.853 | 0.443 | 0.750 | 3/4" | 19.0 mm |

| T100 | 0.853 | 0.447 | 0.750 | 3/4" | 19.0 mm |

| N110 | 1.125 | 0.623 | 1.000 | 1" | 25.4 mm |

| L110 | 1.125 | 0.600 | 1.000 | 1" | 25.4 mm |

| T110 | 1.125 | 0.600 | 1.000 | 1" | 25.4 mm |

600 Series

The 600 Series barbs are designed for use with silicone, C-Flex® and PVC tubing sizes commonly used in biopharm and other applications. Tubing is expanded from 18% to 34% above its nominal ID to maintain a low profile and ease of assembly, and the straight barb stem facilitates use of recommended cable tie retainers or hose clamps.

600 Series Technical Information

| 600 Series Barb Dimensions | Tube Internal Diameter | ||||

|---|---|---|---|---|---|

| Barb Size | Barb OD | Barb ID | Decimal | Fraction | Metric |

| 630 | 0.188 | 0.085 | 0.125 | 1/8" | 3.2 mm |

| N655 | 0.335 | 0.181 | 0.250 | 1/4" | 6.4 mm |

| N670 | 0.490 | 0.296 | 0.375 | 3/8" | 9.5 mm |

| N680 | 0.625 | 0.403 | 0.500 | 1/2" | 12.7 mm |

| N690 | 0.762 | 0.499 | 0.625 | 5/8" | 16.0 mm |

| N6100 | 0.900 | 0.615 | 0.750 | 3/4" | 19.0 mm |

| N6110 | 1.180 | 0.804 | 1.000 | 1" | 25.4 mm |

| T670 | 0.490 | 0.286 | 0.375 | 3/8" | 9.5 mm |

| T680 | 0.625 | 0.399 | 0.500 | 1/2" | 12.7 mm |

| T690 | 0.762 | 0.483 | 0.625 | 5/8" | 16.0 mm |

| Y670 | 0.490 | 0.296 | 0.375 | 3/8" | 9.5 mm |

| Y680 | 0.625 | 0.401 | 0.500 | 1/2" | 12.7 mm |

700 Series

The 700 Series barb is designed for use with Nordson MEDICAL's XQ Series quick connect fittings. This unique single barb is available in sizes to fit the 1/4" (6.4 mm) and 3/8" (9.5 mm) ID tubing sizes and materials commonly used in disposable and reusable medical equipment. Reinforced PVC, unreinforced PVC and polyurethane tubing materials are most commonly used with XQ Series products.

700 Series Technical Information

| 700 Series Barb Dimensions | Tube Internal Diameter | ||||

|---|---|---|---|---|---|

| Barb Size | Barb OD | Barb ID | Decimal | Fraction | Metric |

| 755 | 0.329 | 0.204 | 0.250 | 1/4" | 6.4 mm |

| 770 | 0.450 | 0.302 | 0.375 | 3/8" | 9.5 mm |

900 Series

The 900 Series offers outstanding performance characteristics when used with flexible tubing. Tubing is expanded from 8% to 17% above its nominal ID. This barb provides high flow efficiency and excellent tensile strength. A hose clamp is recommended for this series.

900 Series Technical Information

| 900 Series Barb Dimensions | Tube Internal Diameter | ||||

|---|---|---|---|---|---|

| Barb Size | Barb OD | Barb ID | Decimal | Fraction | Metric |

| 970 | 0.437 | 0.269 | 0.375 | 3/8" | 9.5 mm |

| 975 | 0.573 | 0.358 | 0.500 | 1/2" | 12.7 mm |

3200 Series

Originally created for semi-rigid tubing, this series is preferred for applications where stiffer tubing, like Polyurethane and thicker PVC tubing with harder durometers, is generally used. The 3200 Series expands the tubing between 20% and 50% above its nominal inside diameter. The 3200 Series barb is designed for use with Nordson MEDICAL's PQC Series quick connect fittings. This unique triple barb is available in sizes to fit the 1/8" (3.175 mm) and 1/4" (6.4 mm) ID tubing sizes and materials commonly used in medical device and diagnostics, chemical dispensing, industrial, and compression therapy applications.

3200 Series Technical Information

| 3200 Series Barb Dimensions | Tube Internal Diameter | ||||

|---|---|---|---|---|---|

| Barb Size | Barb OD | Barb ID | Decimal | Fraction | Metric |

| 3230 | 0.188" | 0.059" | 0.500 | 1/8" | 3.2 mm |

| 3260 | 0.300" | 0.150" | 0.200 | 1/4" | 6.4 mm |

Classic Series

The Classic Series is characterized by a longer barb that extends the sealing surface of the fitting. Tubing is expanded from 42% to 69% above its nominal inside diameter. Allows for greater sealing capability with smaller diameters, and easier assembly as the barb size increases.

Classic Series Technical Information

| Classic Series Barb Dimensions | Tube Internal Diameter | ||||

|---|---|---|---|---|---|

| Barb Size | Barb OD | Barb ID | Decimal | Fraction | Metric |

| 10 | 0.105 | 0.046 | 0.063 | 1/16" | 1.6 mm |

| 20 | 0.145 | 0.060 | 0.094 | 3/32" | 2.4 mm |

| 30 | 0.187 | 0.078 | 0.125 | 1/8" | 3.2 mm |

| 40 | 0.234 | 0.100 | 0.156 | 5/32" | 4.0 mm |

| 50 | 0.280 | 0.130 | 0.188 | 3/16" | 4.8 mm |

| 60 | 0.355 | 0.187 | 0.250 | 1/4" | 6.4 mm |

Linkedin

Linkedin